Processing a Return

In a typical return’s scenario, materials brought from supplier can be returned due to various reasons such as quality, early delivery, etc. Buyers create a return purchase order and ship the material back to the supplier, further they can create credit memo for the return parts.

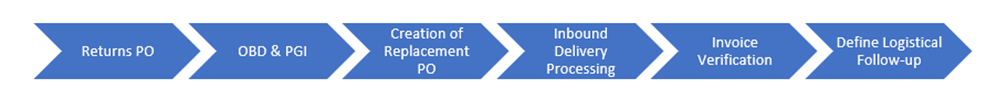

Return process flow:

However, for return cases most of the time replacement parts are requested back from the vendor via a new PO, here another invoice must be created in such case. The process includes manual work and is cumbersome.

Replacement Process Flow:

Detailed Process Flow

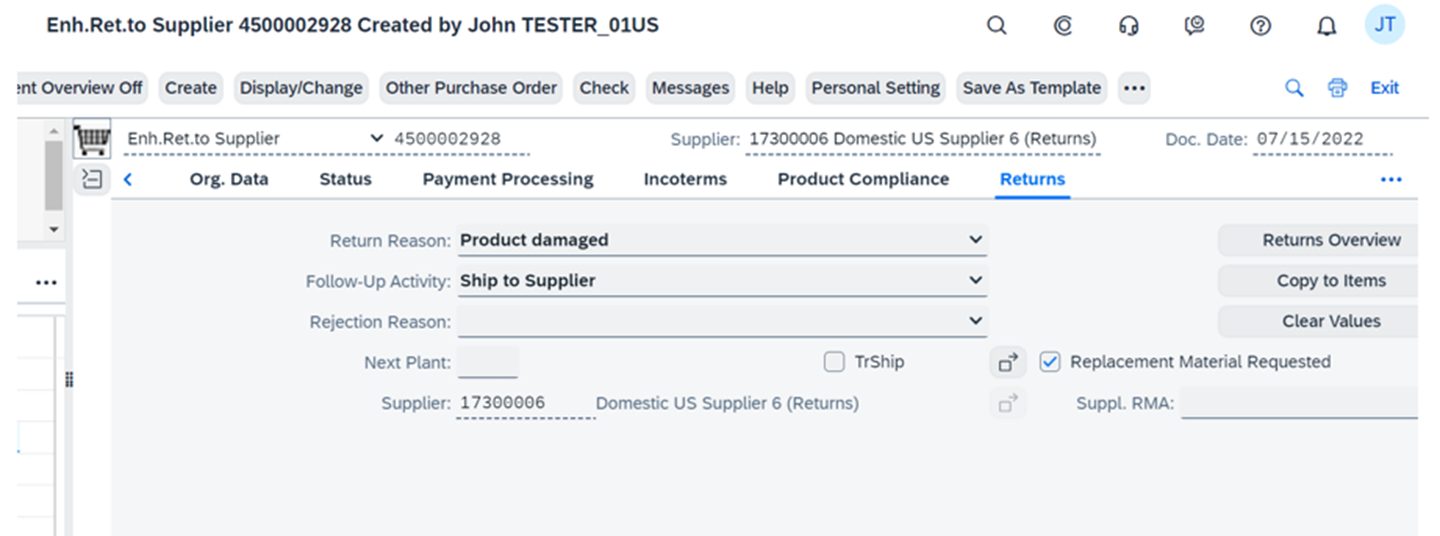

1.) Purchaser creates returns PO, Doc Type – NB2 via app Create Purchase Order – Advanced (ME21N)

- Returns tab will be visible in both Header and Item level.

- Tick Replacement Material Requested.

- Return Reason, Supplier RMA No can be provided for further analysis in Returns Tab.

2.) Create Outbound Delivery via My Purchase Orders – Due for Delivery (VL10B).

3.) Pick and Post Goods Issue via Change Outbound Delivery (VL02N).

Note – After Posting Goods Issue, Credit Memo can be created (Optional) even if Replacement Material Requested is tick in PO. Refer Note – 2887955

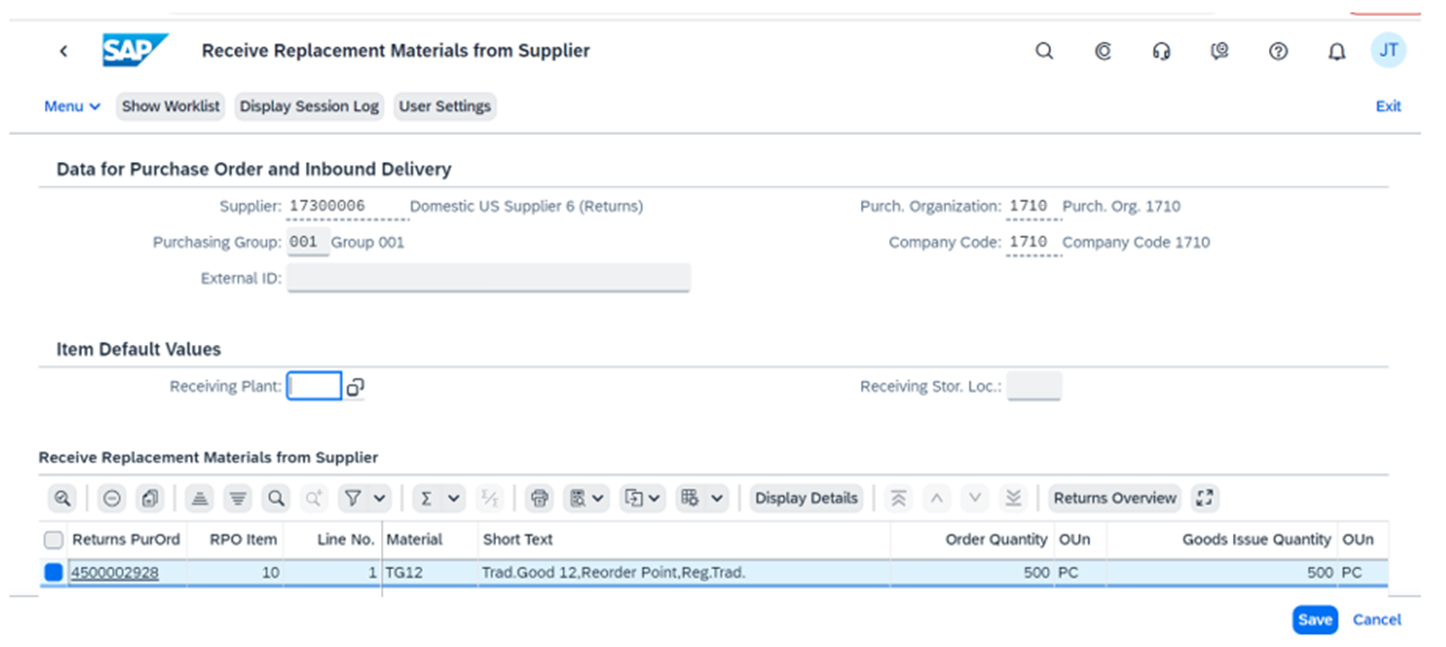

4.) Create Replacement PO via Receive Replacement Materials – From Vendor (MSR_VRM_GR).

- Provide suitable selection criteria and search for return PO.

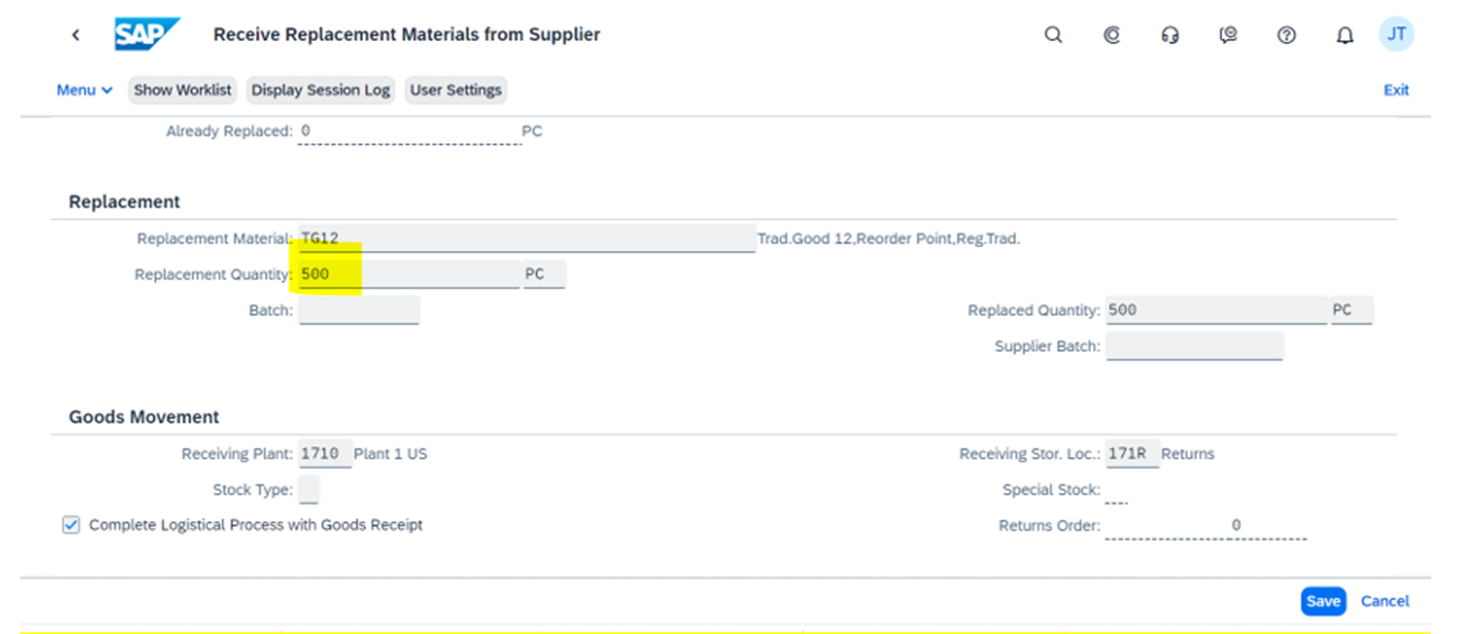

- Once Return PO is displayed in App, click on the Item and navigate to Replacement Subsection to provide replacement quantity, Replacement Quantity should be equal to quantity in Return PO.

- Multiple options for stock movements are also available which can be used according to requirement.

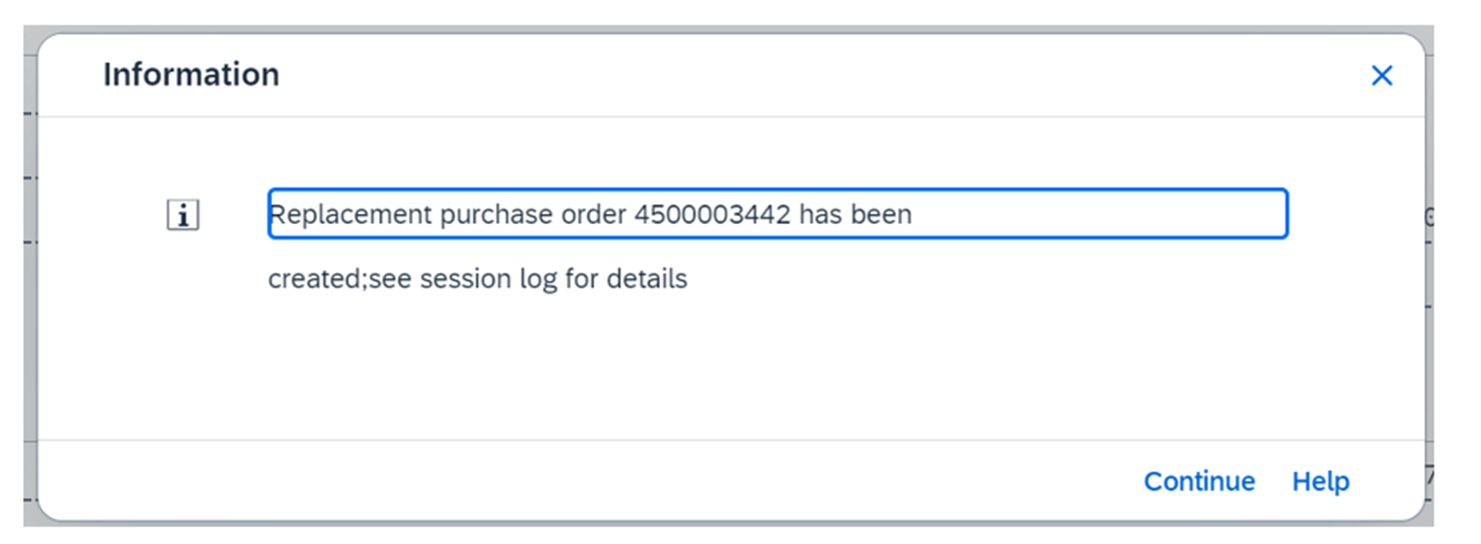

- Click Save – Replacement PO will be created.

Note – Replacement PO will not be visible in Return PO Purchase Order History tab.

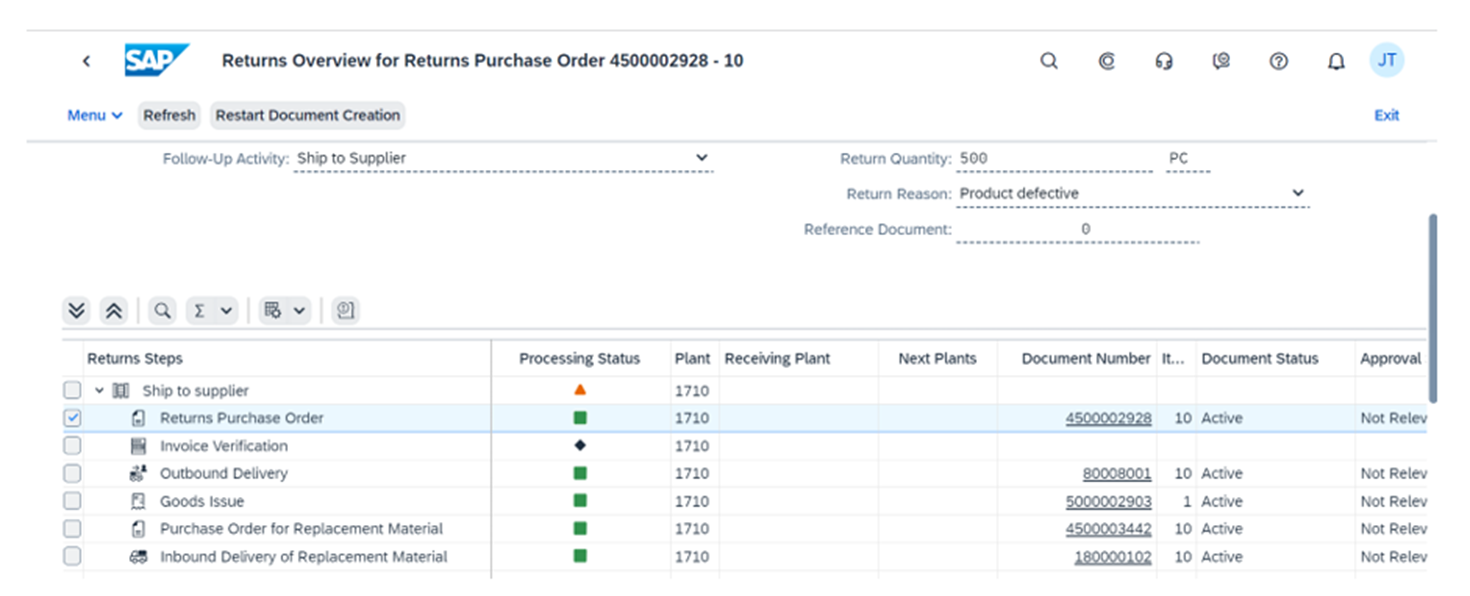

5.) Follow Up Activity

- In Receive Replacement Materials from Vendor app select Returns Purchase Order line and click on Return Overview to display Return Steps.

- System automatically creates Inbound Delivery against Replacement PO. Note Inbound Delivery No.

6.) Goods Receipt via app Change Inbound Delivery (VL32N).

- Add Put away quantity and Perform Goods Receipt.

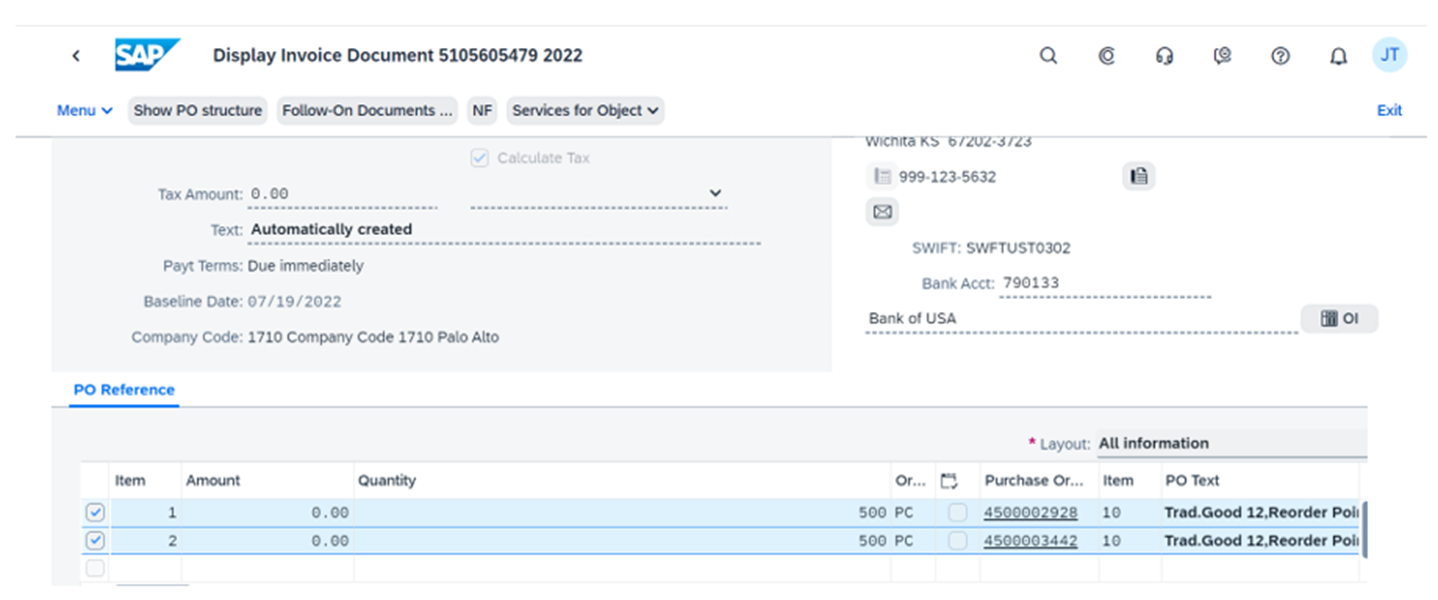

7.) Check Invoice Document via Display Purchase Order – Advanced (ME23N).

- Once GR is done, system automatically creates a document in Invoice Verification that serves both as a credit memo and an invoice with value 0.

Advanced Return Process for Replenishment Materials completes with above steps.